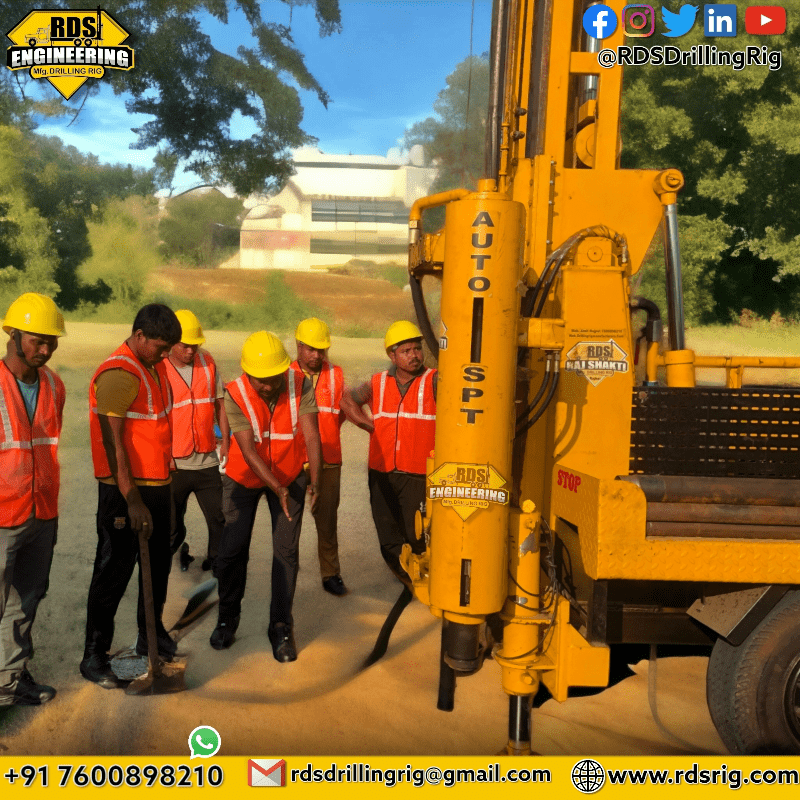

Auto SPT Hammer RDS Engineering Manufacturing Auto SPT Hammer drop hammer that is hydraulically powered and entirely automated. The hammer produces a reliable and precise blow count using a 63.5 kg driving force (slug) dropped from 76 cm, 760mm Adjustable. Both a swing-arm mounted variant and a solo winch line device are offered for the hammer. Both designs may be used for practically any equipment. Compared to conventional manual SPT procedures, the fully enclosed, hydraulic motor powered hammer is far safer. The straightforward, durable design minimizes maintenance while maintaining great efficiency. For all RDS rig variants as well as typical rival equipment, we provide mounting and hydraulic connection kits. According to ISO 22476-3:2005, the RDS automated SPT hammer delivers exceptionally reliable and accurate Standard Penetration Test results. There are no wires or ropes to obstruct the weight's free fall, and a viewing hole enables you to confirm the 30 inch fall height. All moving parts, including the region that is likely to be hit by the weight or anvil, are also encased for safety. RDS Engineering installs more than 80 Auto SPT Drilling Rigs. Geotechnical Testing Equipment as per ISO 22476-3:2005 RDS Auto SPT Hammer Technical Specifications Hammer drop height: 760mm, 76cm, 30 inches, Hammer piston weight: 63.5 Kg, 140 lbs Blow per minute: 10-30 Adjustable System Energy test ratio (ETR): 67% - 80% Adjustable System SPT Assembly: SPT Sampler, SPT tube, SPT shoe SPT Anvil Connection: AW / Customize SPT Automatic Hammer Benefits 1. Easy to Upgrade Your Existing Rig 2. Tests with high reliability and accuracy (63.5 kg x 760mm drop) (140 lbs. x 30" drop) 3. Safety: the hammer's casing contains all of the working parts. 4. Can be applied to the majority of rigs (geotechnical, rotary, diamond core rig) 5. Accuracy results in N-value and SPT test, SBC Test Easy to Set Up The SPT (Standard Penetration Test) Hammer assembly is kept to the right of the drill frame and secured in place for travel. The Hammer must be raised using a hydraulic cylinder or hoist and placed above the drill rod in order to work. The Hammer case is lowered into the driving position so that it may be rapidly positioned above the borehole. Simple to Use The Hammer's design is straightforward, and a single operator can operate it successfully. Insofar as their performance doesn't depend on operator-controlled adjustments or monitoring, RDS SPT Hammers are totally automated. The weight of the slug is raised hydraulically via a continuous chain; Due to the Hammer case's ability to "float" in the self-compensating rack or on the hydraulic cylinder, the sampling procedure may be followed regardless of the material density. For better safety, the hitting surface is kept totally enclosed. The normal penetration test is carried out by the RDS Self-Compensating SPT Hammer without adding any extra weight or pressure to the drill string. This eliminates the possibility of retroactive loads or forces being applied to the drill string each time the mechanism cycles. FAQ Terms & Conditions of Ordering: Quality warranty: Our products are made of high-quality steel and all spare parts are inspected strictly before shipping. We have quickly responded to your complaint and suggestion. Production time: Generally need 15 days Transportation: By air, By Express or by sea according to your requests. 1. Methods of Payment: RTGST, NEFT, IMPS, CASH, Online 2. Handling time for an order Based on order quantity, normally it takes 2 days for production. in 3 working days after receiving the advance payment 3. Shipping way Sample order: we suggest Courier express like DHL/UPS/TNT/FEDEX or by air Bulk order: we suggest by air or by sea. 4. Quality Control We have our own experienced QC. There will be strict inspection and testing for every order before shipping out. 5. After Services: a. Our sales team will respond to your question within 24 hours (Holidays Excluded) b. Technical Support will be available at any time 6. Quality & Service: A. There will be strict inspection and testing for every order before shipping out. B. Our sales team and Technical Support will respond to your question within 24 hours through WhatsApp at +91 7600898210 C. Free replacement will provide once the failure is confirmed caused or our product quality; Not satisfied with a refund. For more information, please contact: RDS Drilling Rig. WhatsApp: +91 7600898210 Email: rdsdrillingrig@gmail.com Website: https://www.rdsrig.com

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

2023-08-01T03:20:09

Auto SPT Hammer RDS Engineering Manufacturing Auto SPT Hammer drop hammer that is hydraulically powered and entirely automated. The hammer produces a reliable and precise blow count using a 63.5 kg driving force (slug) dropped from 76 cm, 760mm Adjustable. Both a swing-arm mounted variant and a solo winch line device are offered for the hammer. Both designs may be used for practically any equipment. Compared to conventional manual SPT procedures, the fully enclosed, hydraulic motor powered hammer is far safer. The straightforward, durable design minimizes maintenance while maintaining great efficiency. For all RDS rig variants as well as typical rival equipment, we provide mounting and hydraulic connection kits. According to ISO 22476-3:2005, the RDS automated SPT hammer delivers exceptionally reliable and accurate Standard Penetration Test results. There are no wires or ropes to obstruct the weight's free fall, and a viewing hole enables you to confirm the 30 inch fall height. All moving parts, including the region that is likely to be hit by the weight or anvil, are also encased for safety. RDS Engineering installs more than 80 Auto SPT Drilling Rigs. Geotechnical Testing Equipment as per ISO 22476-3:2005 RDS Auto SPT Hammer Technical Specifications Hammer drop height: 760mm, 76cm, 30 inches, Hammer piston weight: 63.5 Kg, 140 lbs Blow per minute: 10-30 Adjustable System Energy test ratio (ETR): 67% - 80% Adjustable System SPT Assembly: SPT Sampler, SPT tube, SPT shoe SPT Anvil Connection: AW / Customize SPT Automatic Hammer Benefits 1. Easy to Upgrade Your Existing Rig 2. Tests with high reliability and accuracy (63.5 kg x 760mm drop) (140 lbs. x 30" drop) 3. Safety: the hammer's casing contains all of the working parts. 4. Can be applied to the majority of rigs (geotechnical, rotary, diamond core rig) 5. Accuracy results in N-value and SPT test, SBC Test Easy to Set Up The SPT (Standard Penetration Test) Hammer assembly is kept to the right of the drill frame and secured in place for travel. The Hammer must be raised using a hydraulic cylinder or hoist and placed above the drill rod in order to work. The Hammer case is lowered into the driving position so that it may be rapidly positioned above the borehole. Simple to Use The Hammer's design is straightforward, and a single operator can operate it successfully. Insofar as their performance doesn't depend on operator-controlled adjustments or monitoring, RDS SPT Hammers are totally automated. The weight of the slug is raised hydraulically via a continuous chain; Due to the Hammer case's ability to "float" in the self-compensating rack or on the hydraulic cylinder, the sampling procedure may be followed regardless of the material density. For better safety, the hitting surface is kept totally enclosed. The normal penetration test is carried out by the RDS Self-Compensating SPT Hammer without adding any extra weight or pressure to the drill string. This eliminates the possibility of retroactive loads or forces being applied to the drill string each time the mechanism cycles. FAQ Terms & Conditions of Ordering: Quality warranty: Our products are made of high-quality steel and all spare parts are inspected strictly before shipping. We have quickly responded to your complaint and suggestion. Production time: Generally need 15 days Transportation: By air, By Express or by sea according to your requests. 1. Methods of Payment: RTGST, NEFT, IMPS, CASH, Online 2. Handling time for an order Based on order quantity, normally it takes 2 days for production. in 3 working days after receiving the advance payment 3. Shipping way Sample order: we suggest Courier express like DHL/UPS/TNT/FEDEX or by air Bulk order: we suggest by air or by sea. 4. Quality Control We have our own experienced QC. There will be strict inspection and testing for every order before shipping out. 5. After Services: a. Our sales team will respond to your question within 24 hours (Holidays Excluded) b. Technical Support will be available at any time 6. Quality & Service: A. There will be strict inspection and testing for every order before shipping out. B. Our sales team and Technical Support will respond to your question within 24 hours through WhatsApp at +91 7600898210 C. Free replacement will provide once the failure is confirmed caused or our product quality; Not satisfied with a refund. For more information, please contact: RDS Drilling Rig. WhatsApp: +91 7600898210 Email: rdsdrillingrig@gmail.com Website: https://www.rdsrig.com

2023-08-01T03:20:09

Keywords

- 4.

- 1.

- AW

- B.

- a.

- air

- sea

- ISO

- FAQ

- NEFT

- IMPS

- CASH

- slug

- hoist

- right

- Tests

- Terms

- 76 cm

- wires

- ropes

- RTGST

- region

- casing

- 2 days

- travel

- minute

- cycles

- safety

- forces

- refund

- N-value

- 15 days

- Website

- Express

- failure

- designs

- Methods

- Courier

- Services

- question

- Holidays

- majority

- mounting

- reliable

- 24 hours

- Ordering

- requests

- 30" drop

- SPT test

- SPT tube

- SPT shoe

- products

- borehole

- SBC Test

- pressure

- mechanism

- free fall

- complaint

- 30 inches

- Customize

- drill rod

- suggestion

- Bulk order

- sales team

- Conditions

- monitoring

- possibility

- performance

- maintenance

- SPT Sampler

- information

- drill frame

- spare parts

- Shipping way

- 140 lbs Blow

- Sample order

- extra weight

- SPT Assembly

- viewing hole

- moving parts

- drill string

- working parts

- order quantity

- Transportation

- 3 working days

- The Hammer case

- RDS SPT Hammers

- single operator

- Production time

- Quality Control

- hitting surface

- product quality

- advance payment

- experienced QC.

- Accuracy results

- Quality warranty

- material density

- driving position

- great efficiency

- high reliability

- continuous chain

- RDS rig variants

- RDS Drilling Rig.

- retroactive loads

- strict inspection

- Technical Support

- DHL/UPS/TNT/FEDEX

- Energy test ratio

- precise blow count

- sampling procedure

- hydraulic cylinder

- high-quality steel

- Hammer drop height

- C. Free replacement

- 30 inch fall height

- Hammer piston weight

- SPT Anvil Connection

- 63.5 kg driving force

- 80% Adjustable System

- solo winch line device

- self-compensating rack

- 10-30 Adjustable System

- normal penetration test

- typical rival equipment

- RDS automated SPT hammer

- hydraulic connection kits

- swing-arm mounted variant

- 80 Auto SPT Drilling Rigs

- SPT Automatic Hammer Benefits

- hydraulic motor powered hammer

- Geotechnical Testing Equipment

- operator-controlled adjustments

- straightforward, durable design

- RDS Self-Compensating SPT Hammer

- conventional manual SPT procedures

- geotechnical, rotary, diamond core rig

- Standard Penetration Test) Hammer assembly

- accurate Standard Penetration Test results

- RDS Auto SPT Hammer Technical Specifications

- RDS Engineering Manufacturing Auto SPT Hammer drop hammer

Submit Your Enquiry